What is interference fit? It’s a fascinating joining technique used extensively in engineering, creating strong, reliable connections. This method involves precisely fitting two parts together, where one part is slightly larger than the other, creating a snug, interference fit. Understanding this technique is crucial for various applications, from simple mechanical assemblies to intricate aerospace components.

This comprehensive guide delves into the intricacies of interference fits, exploring their definition, types, calculations, advantages, disadvantages, manufacturing processes, design considerations, and applications across diverse engineering fields. We’ll also examine troubleshooting strategies and maintenance procedures for ensuring optimal performance and longevity.

Definition and Overview

Interference fits are a crucial aspect of mechanical engineering, enabling precise and secure assembly of components. They leverage the principle of interference to create a strong, reliable connection between parts. This approach ensures that parts remain in place without relying solely on fasteners. Understanding the nuances of interference fits is vital for achieving optimal performance and longevity in engineered systems.

Definition of Interference Fit

An interference fit is a joining method where one component is precisely sized to fit tightly within another. This creates a frictional force that holds the components together. The difference in size between the components is carefully controlled to achieve the desired level of tightness. This approach is particularly useful for applications requiring high load-bearing capacity and resistance to relative movement.

Key Characteristics of Interference Fits

Interference fits are characterized by their precise tolerances, which control the amount of interference. The high degree of accuracy in sizing is essential for a reliable and consistent fit. Furthermore, the controlled interference leads to a strong and secure connection. This characteristic is crucial in applications demanding minimal movement and high load-bearing capacity. The fit is designed to prevent relative motion between the parts.

Types of Interference Fits

Interference fits are categorized into different types based on the degree of interference. These types include tight, medium, and loose fits. The classification is based on the level of force required to assemble the parts.

- Tight fits: These fits feature a significant amount of interference, resulting in a very strong connection. They require considerable force for assembly and often utilize specialized tooling or procedures. They are suitable for applications where high load-bearing capacity and prevention of relative movement are paramount.

- Medium fits: These fits strike a balance between tight and loose fits, providing a moderate level of interference. They offer a compromise between strength and ease of assembly, suitable for a wide range of applications. They are frequently used in situations where moderate load-bearing capacity and some degree of relative movement are acceptable.

- Loose fits: These fits have a minimal amount of interference. They are relatively easy to assemble and disassemble, making them suitable for applications where ease of maintenance or frequent adjustments are necessary. However, they offer less load-bearing capacity compared to tight fits.

Applications of Interference Fits

Interference fits find extensive use in various engineering disciplines. They are employed in applications ranging from aerospace to automotive, and beyond. Their ability to provide a strong, secure connection while maintaining dimensional stability makes them a versatile choice for diverse needs.

- Aerospace: Interference fits are crucial in aircraft engines and other components where high loads and minimal movement are essential. They are used to connect shafts and bearings, ensuring smooth operation and stability.

- Automotive: Interference fits are used in automotive transmissions, wheel hubs, and other critical components. Their strength and stability contribute to vehicle performance and safety.

- Mechanical Engineering: Interference fits are integral in various mechanical components, ensuring precise alignment and functionality. They are used in machinery to connect components and maintain their integrity.

Comparison of Interference Fit Types

The following table provides a comparative overview of different interference fit types, highlighting their tolerances and common applications.

| Fit Type | Tolerance | Application | Assembly Difficulty |

|---|---|---|---|

| Tight | Very tight tolerances (e.g., +/- 0.001 inches) | High load applications, precise alignment critical | High |

| Medium | Moderate tolerances (e.g., +/- 0.005 inches) | General mechanical assemblies, moderate load bearing | Medium |

| Loose | Wider tolerances (e.g., +/- 0.010 inches) | Components requiring ease of assembly and disassembly | Low |

Measurement and Calculation

Determining the interference fit between two components necessitates precise measurement and calculation techniques. Accurate assessment of the interference value is crucial for ensuring proper assembly and function in various engineering applications. This section Artikels the methods for measuring interference, the formulas used for calculation, and provides practical examples.Understanding the interference value is paramount in mechanical engineering. Precise calculations help predict the behavior of parts under stress and ensure reliable performance.

This detailed analysis allows for effective design optimization and cost reduction.

Methods for Measuring Interference

Accurate measurement of interference relies on precise methods. Direct measurement of the gap between components is often employed using specialized instruments. Micrometers, calipers, and laser interferometers are commonly used tools. These tools provide highly accurate measurements, critical for precise interference fit calculations. Carefully controlled conditions are essential for reliable measurement.

Formulas for Calculating Interference Fit

Several formulas are available for calculating interference fits. The choice of formula depends on the specific geometry of the parts involved. The most fundamental formula involves calculating the difference between the outer diameter of the larger part and the inner diameter of the smaller part.

Interference (I) = Outer Diameter (OD)

Inner Diameter (ID)

This formula is directly applicable for simple cylindrical parts.

Calculating the Interference Value

To calculate the interference value, first identify the relevant dimensions of the components. The outer diameter of the larger part and the inner diameter of the smaller part are the key measurements. Subtract the inner diameter from the outer diameter to obtain the interference value. A positive value indicates interference; a negative value indicates clearance.

So, like, interference fit is when parts are made slightly bigger, right? It’s all about the tiny gaps and how they kinda mesh together, you know? But, if you’re tryna figure out if Planet Fitness even has a family membership, then check this out: does planet fitness have a family membership. Basically, it’s all about precision engineering, making sure everything fits perfectly, even if it’s just a gym membership for your whole fam.

So yeah, interference fit, it’s all about the close tolerances.

Examples of Interference Fit Calculations

Consider a scenario where a shaft with an outer diameter of 25 mm is fitted into a hole with an inner diameter of 24.8 mm. Applying the formula:

Interference (I) = 25 mm – 24.8 mm = 0.2 mm

This positive value of 0.2 mm signifies an interference fit.Another example: A shaft with an outer diameter of 30 mm is fitted into a hole with an inner diameter of 30.2 mm. Applying the formula:

Interference (I) = 30 mm – 30.2 mm = -0.2 mm

This negative value of -0.2 mm signifies a clearance fit.

Table of Formulas and Applications

| Formula | Application |

|---|---|

| Interference (I) = OD – ID | Calculating interference for cylindrical components. |

Advantages and Disadvantages of Interference Fits

Interference fits, a crucial joining technique in engineering, offer a robust and reliable method for assembling components. Understanding their strengths and weaknesses, alongside comparison with alternative joining methods, is vital for informed design decisions. This section delves into the advantages and disadvantages of interference fits, highlighting specific applications where they excel.

Advantages of Interference Fits

Interference fits provide several advantages in engineering applications. They offer high load-carrying capacity and excellent resistance to axial and lateral displacement. This inherent strength stems from the frictional force generated by the interference.

- High Load-Carrying Capacity: The significant friction generated by the interference prevents relative movement between the parts, leading to a robust assembly that can withstand substantial loads. This is particularly advantageous in applications requiring high mechanical strength.

- Excellent Resistance to Misalignment and Displacement: The interference fit effectively resists axial and lateral movement. This stability is crucial in applications where precise positioning is critical, such as in rotating machinery.

- Ease of Assembly (in some cases): Properly designed interference fits can be relatively easy to assemble, requiring minimal specialized tools. This contrasts with other methods like welding, which might necessitate skilled labor and specialized equipment.

- Permanent Joints (in many cases): In some instances, interference fits result in permanent joints, reducing the need for frequent reassembly. This is a major advantage in situations where disassembling the components is undesirable or difficult.

Disadvantages of Interference Fits

Despite their advantages, interference fits also have limitations. One significant disadvantage is the difficulty in achieving precise fit tolerances and potential issues with dimensional variations.

- Difficulty in Achieving Precise Fit Tolerances: Manufacturing components to precise interference fit tolerances can be challenging, requiring careful control over manufacturing processes. Variations in material properties or machining errors can affect the final fit, potentially leading to assembly issues.

- Potential for Distortion or Damage: Significant interference can cause deformation in one or both components, especially if the material properties are not well understood. This distortion can affect the functionality of the parts.

- Limited Disassembly: Once assembled, interference fits are often difficult to disassemble without damaging the components. This is a drawback in situations where frequent maintenance or repairs are anticipated.

- Material Selection Constraints: The choice of materials is limited by the requirement for compatibility and dimensional stability during assembly and operation. Some materials may not tolerate the stresses generated during the fitting process.

Comparison with Other Joining Methods

Interference fits differ significantly from other joining methods, each with its own set of strengths and weaknesses. Choosing the right method depends on the specific application’s requirements.

| Joining Method | Advantages | Disadvantages |

|---|---|---|

| Interference Fit | High load-carrying capacity, resistance to misalignment, often ease of assembly | Difficulty in achieving precise fit, potential for distortion, limited disassembly |

| Welding | High strength, permanent bond | Complex processes, high energy input, potential for heat-affected zone |

| Bolting | Easy assembly and disassembly, adjustable tightness | Lower load-carrying capacity, susceptible to loosening |

| Riveting | Permanent bond, moderate strength | Limited adjustability, potential for material deformation |

Specific Scenarios Where Interference Fits Are Preferable

Interference fits are particularly well-suited for applications requiring high load-carrying capacity and precise alignment.

- Rotating Machinery Components: Interference fits are frequently used in shafts and hubs of rotating machinery to ensure stable and secure operation.

- High-Precision Instruments: The stability and alignment offered by interference fits are crucial in high-precision instruments.

- Applications Requiring Permanent Joints: Interference fits are a good option when a permanent bond is needed, eliminating the need for periodic adjustments.

Manufacturing and Assembly: What Is Interference Fit

Interference fits, crucial in various engineering applications, necessitate precise manufacturing and assembly procedures. Understanding these processes is essential for achieving the desired fit and functionality. Careful consideration of the manufacturing methods and assembly techniques is vital for ensuring the integrity and longevity of the final product.

Manufacturing Processes for Interference Fits

Precise manufacturing is key to achieving the intended interference fit. Different materials and geometries require tailored approaches. Material properties, such as hardness and ductility, significantly influence the selection of manufacturing processes. The complexity of the part geometry further dictates the manufacturing methods.

- Machining: This process, encompassing turning, milling, and drilling, is widely used for creating interference fits in metallic parts. Controlled cutting and shaping ensure precise dimensions and tolerances, critical for achieving the desired interference. For instance, turning a shaft to a smaller diameter than the intended hole in the housing, ensuring a snug fit, is a common machining application for interference fits.

- Casting: For complex shapes or large quantities, casting methods like sand casting or die casting are often employed. However, maintaining precise tolerances for interference fits in castings can be challenging, requiring careful mold design and quality control measures.

- Forging: For parts demanding high strength and durability, forging methods can create parts with tight tolerances, well-suited for interference fits. The forging process often results in a dense material structure, contributing to the part’s strength and reliability in interference fit applications.

- Powder Metallurgy: For parts requiring specific material properties or intricate geometries, powder metallurgy methods are employed. This approach involves compacting and sintering powdered metal to form the desired shape. It can offer good control over the material’s properties, enabling precise interference fits.

Assembly Procedures for Interference Fits

Correct assembly procedures are crucial for achieving the intended interference fit. Incorrect procedures can lead to damage to the parts or difficulties in subsequent operations. Proper handling and lubrication are important considerations.

- Press Fitting: This method involves applying force to press a part into another part. Appropriate tooling and force control are vital to prevent damage. The force required depends on the material properties, the interference, and the geometry of the parts.

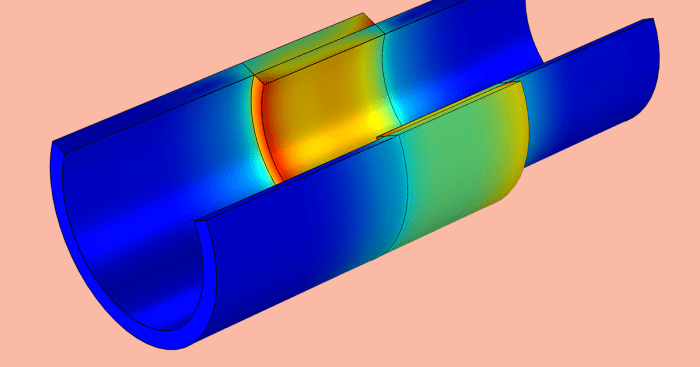

- Shrink Fitting: This method utilizes thermal expansion and contraction to create a tight fit. Heating one part and cooling the other creates the interference. Careful temperature control and precise heating and cooling are necessary for accurate fit.

- Mechanical Fasteners: In some cases, interference fits can be combined with mechanical fasteners, like screws or bolts, for additional security and support. These fasteners offer an additional layer of protection, ensuring the components remain firmly joined.

Challenges in Assembling Interference Fits

Several challenges can arise during the assembly of interference fits. These issues often stem from mismatched tolerances, material variations, or improper assembly procedures.

- Dimensional Variations: Slight variations in the dimensions of the parts can lead to difficulties in achieving the intended interference fit. Manufacturing tolerances must be carefully considered to ensure a snug fit without excessive force.

- Material Properties: Differences in the material properties of the parts can affect the assembly process. Different materials react differently to the application of force. Understanding these differences is crucial for successful assembly.

- Improper Lubrication: Lack of or improper lubrication can lead to friction and binding during the assembly process. Appropriate lubricants help in reducing friction and facilitating smooth assembly.

- Equipment Limitations: The equipment used for the assembly process might not be capable of handling the required forces or tolerances. Adequate equipment is crucial for preventing damage to the parts or the assembly process.

Strategies for Preventing Assembly Issues

Several strategies can be employed to prevent or mitigate assembly issues associated with interference fits. These include careful selection of materials, precise manufacturing processes, and meticulous assembly procedures.

- Tolerances: Maintaining tight tolerances in manufacturing is essential for achieving the desired interference fit. Utilizing precision measuring tools during manufacturing and assembly ensures a consistent fit.

- Material Selection: Choosing appropriate materials with consistent properties is crucial. The materials should exhibit the required hardness, ductility, and thermal expansion characteristics.

- Lubrication: Appropriate lubricants should be selected and applied to reduce friction during the assembly process. Proper lubrication reduces wear and tear and facilitates smooth assembly.

- Inspection: Regular inspection during the manufacturing and assembly stages ensures the quality of the parts and the adherence to specifications.

Manufacturing Processes for Different Interference Fit Types

| Interference Fit Type | Manufacturing Processes |

|---|---|

| Press Fit | Machining, Casting, Forging, Powder Metallurgy |

| Shrink Fit | Machining, Forging, Casting, and Heat Treatment |

| Locational Interference Fit | Machining, Precision Casting, and Additive Manufacturing |

Tolerance and Design Considerations

Careful consideration of tolerances is crucial in the successful design and implementation of interference fits. Precisely defined tolerances ensure the desired level of fit, prevent potential assembly difficulties, and guarantee the longevity and reliability of the joined components. Understanding the interplay between material properties, assembly methods, and the specific application requirements is vital for achieving an optimal design.Interference fit design involves a delicate balance between achieving the desired level of friction and avoiding excessive stress on the components.

The appropriate selection of tolerances is fundamental to ensuring proper functionality and longevity. Factors such as material properties, manufacturing processes, and the intended application all play a role in the selection process.

Factors Influencing Tolerance in Interference Fits

Several factors influence the tolerance range for interference fits. Material properties, such as hardness, yield strength, and elasticity, directly impact the amount of interference that can be accommodated without causing damage or deformation. Manufacturing tolerances, resulting from machining or casting processes, also contribute to the overall tolerance range. The complexity of the geometries and the specific application requirements also play a role.

Lastly, the assembly method employed, such as press fitting or shrink fitting, also affects the permissible tolerances.

Choosing Appropriate Tolerances for Interference Fits

Selecting appropriate tolerances involves a systematic evaluation of the various influencing factors. This includes understanding the material properties of both the inner and outer components, considering the manufacturing processes involved, and assessing the specific application needs. A crucial consideration is the desired level of interference. Excessive interference can lead to stress concentrations, potential failure, and difficulties in assembly.

Conversely, insufficient interference may result in a loose fit, compromising the desired functionality. Engineers should carefully evaluate these factors to achieve the optimal balance. Thorough testing and simulations can aid in determining the appropriate tolerance range for a given application.

Impact of Material Properties on Interference Fit Design

The material properties of the components significantly influence the interference fit design. Materials with high hardness and yield strength can accommodate higher levels of interference without permanent deformation. Materials with greater elasticity exhibit more deformation under stress, requiring more conservative tolerance ranges. For instance, materials like hardened steel can withstand greater interference than softer materials like aluminum.

The coefficient of thermal expansion of the materials is also a critical consideration. Mismatched coefficients can lead to stresses and potential issues during operation. Selecting materials with similar coefficients minimizes thermal stresses. Consideration of these properties during the design phase is essential for long-term reliability.

Examples of Interference Fit Designs for Different Applications

Interference fits are widely used in various engineering applications. In automotive engineering, interference fits are used to connect engine components, ensuring precise alignment and functionality. In aerospace engineering, interference fits are employed for critical structural connections, demanding high precision and reliability. Similarly, in mechanical engineering, interference fits are crucial for connecting shafts and housings, enabling smooth rotation and precise positioning.

These examples demonstrate the versatility of interference fits in diverse engineering contexts.

Design Considerations for Interference Fits, What is interference fit

| Design Consideration | Material Selection | Tolerance Ranges | Assembly Methods |

|---|---|---|---|

| Shaft and Housing Assembly | Steel (AISI 1045), Aluminum (6061-T6) | Tight tolerance (e.g., ±0.005 mm) for high precision, ±0.01 mm for general purpose | Press fitting, Shrink fitting |

| Gear and Shaft Connection | Hardened steel (e.g., 4140) | High tolerance for durability and precise engagement | Press fitting, Shrink fitting |

| Bearing Housing | Steel alloys, Ceramics | Tight tolerances for precise alignment and load-bearing capacity | Press fitting |

| Engine Components | Steel, cast iron | Tolerances adjusted for thermal expansion and wear | Shrink fitting |

Applications and Examples

Interference fits find widespread use in various engineering disciplines, particularly where precise and secure connections are paramount. Their adaptability to different materials and geometries makes them a valuable design tool. This section details the diverse applications of interference fits, highlighting specific examples and design considerations.

Mechanical Engineering Applications

Interference fits are fundamental in mechanical engineering, enabling the creation of robust and reliable assemblies. They are used extensively in rotating machinery, such as gears, shafts, and bearings, where precise alignment and secure connections are crucial for optimal performance. The secure grip of an interference fit helps prevent slippage and maintain consistent rotational speed. For instance, in a motor shaft, the interference fit ensures the rotor maintains its proper alignment with the stator, preventing vibrations and ensuring smooth operation.

In conveyor systems, interference fits are critical for connecting components such as rollers and shafts.

Aerospace Engineering Applications

The aerospace industry demands high-precision components that can withstand extreme conditions. Interference fits play a vital role in ensuring the structural integrity and functionality of aircraft components. In aircraft engines, interference fits are used in the connecting rods and other critical components. The high-stress environment of an aircraft engine demands that parts remain securely connected, mitigating the potential for catastrophic failure.

The use of interference fits in these applications requires careful consideration of material selection and manufacturing tolerances to withstand the high temperatures, vibrations, and pressures encountered in flight.

Other Engineering Applications

Beyond mechanical and aerospace engineering, interference fits are used in various other fields. In hydraulic systems, they are used to connect pipes and components, ensuring leak-proof connections. In plumbing systems, they ensure secure connections between pipes and fittings. Their ability to resist vibration and pressure makes them invaluable in these contexts. In electronics, interference fits can be used for mounting components, ensuring stable connections in circuit boards and enclosures.

Design Considerations in Specific Applications

Several factors must be considered when designing interference fits for specific applications. Material compatibility is crucial, as different materials react differently under stress. The desired level of clamping force and the manufacturing process are critical considerations. Furthermore, the operational environment and expected loads on the component are paramount in the design process. Proper tolerance analysis is essential to ensure the fit is consistent and reliable.

Performance Characteristics in Different Environments

The performance of interference fits can vary significantly depending on the environment. In high-temperature environments, the material selection and the fit design must account for thermal expansion and contraction. In high-pressure environments, the fit must be able to withstand the applied forces without compromising the integrity of the connection. The use of specialized lubricants can improve performance in harsh environments.

Table of Applications and Examples

| Industry | Application | Example | Design Considerations |

|---|---|---|---|

| Mechanical Engineering | Rotating Machinery | Motor shafts and gears | Material selection, clamping force, and tolerance analysis |

| Aerospace Engineering | Aircraft Engine Components | Connecting rods | Material properties, thermal expansion, and vibration resistance |

| Hydraulic Systems | Pipe Connections | Hydraulic cylinders and actuators | Leak-proof connections, pressure resistance, and material compatibility |

| Plumbing | Pipe Fittings | Pipes and valves | Leak-proof connections and pressure resistance |

| Electronics | Component Mounting | Circuit boards and enclosures | Stable connections, thermal expansion, and vibration resistance |

Troubleshooting and Maintenance

Maintaining interference fits requires careful attention to potential issues and proactive maintenance strategies. Properly addressing these concerns can prevent costly failures and ensure the long-term reliability of the assembly. This section details common problems, troubleshooting steps, and maintenance procedures for interference fits, along with case studies to illustrate practical applications.

Common Interference Fit Issues

Interference fits, while robust, are susceptible to several issues. Understanding these potential problems is crucial for effective troubleshooting. Misalignments, material degradation, and improper assembly procedures can lead to difficulties.

- Misalignment: A misaligned component can create uneven pressure distribution within the interference fit, leading to localized stress concentrations. This can result in premature wear and potential failure.

- Material Degradation: Factors like corrosion, fatigue, and temperature fluctuations can degrade the material properties of the components. This degradation can reduce the fit’s holding capacity, making it prone to loosening or failure.

- Improper Assembly Procedure: Excessive force during assembly can induce stresses beyond the material’s capacity. This can damage the components and compromise the fit’s integrity. Similarly, insufficient force can result in a weak interference fit, leading to loosening or misalignment.

- Thermal Expansion and Contraction: Significant temperature variations can cause the components to expand and contract differently. This can disrupt the interference fit, resulting in looseness or binding, depending on the direction of the thermal change.

Troubleshooting Steps for Interference Fit Problems

A systematic approach is vital for effectively addressing interference fit issues. Thorough inspection and evaluation of the components and assembly procedure are critical.

- Visual Inspection: Carefully examine the fit for any signs of misalignment, deformation, or corrosion. Look for any visible damage or wear to the components, especially at the interference zone.

- Dimensional Measurement: Accurately measure the dimensions of the interacting components to identify any discrepancies from the design specifications. Utilize precision measuring tools to detect minute variations.

- Force Analysis: Evaluate the forces involved during assembly and operation. Analyze the potential stress concentrations within the interference zone. Identify any excessive or insufficient forces that might be contributing to the problem.

- Material Analysis: If material degradation is suspected, perform tests to determine the material’s current properties, such as hardness, tensile strength, and yield strength. Compare these values to the original specifications.

- Assembly Procedure Review: Analyze the assembly procedure to identify any deviations from the recommended process. Examine the application of force, the sequence of assembly steps, and the tools used.

Maintenance Procedures for Interference Fits

Proactive maintenance is essential to prolong the lifespan of interference fits. Regular inspections and appropriate handling are key.

- Regular Inspections: Implement a schedule for periodic inspections of interference fits, focusing on visual checks and dimensional measurements. Document findings and address any identified issues promptly.

- Environmental Controls: Maintain appropriate environmental conditions to minimize material degradation. Control factors like temperature, humidity, and exposure to corrosive agents.

- Proper Handling: Use appropriate handling techniques during assembly and maintenance to prevent damage to the components and the interference fit.

Case Studies

Numerous successful case studies demonstrate the effectiveness of these troubleshooting and maintenance procedures. For instance, a manufacturing plant found that inconsistencies in assembly pressure were causing interference fit failures. By refining the assembly procedure and introducing pressure monitoring systems, they significantly reduced the failure rate. Another example highlights the importance of periodic inspections; an early detection of corrosion in a critical interference fit prevented a costly equipment failure.

Troubleshooting Table

| Common Problem | Troubleshooting Steps |

|---|---|

| Misalignment | Visual inspection, precise dimensional measurement, recalibration of assembly equipment |

| Material Degradation | Material testing (e.g., hardness, tensile strength), environmental analysis, corrosion prevention measures |

| Improper Assembly | Review assembly procedure, use calibrated tools, re-train personnel |

| Thermal Expansion/Contraction | Evaluate thermal gradients, use thermal management systems, consider material selection |

Outcome Summary

In conclusion, interference fits offer a powerful and versatile joining method, providing robust connections with specific advantages and considerations. From choosing the right tolerances to understanding manufacturing and assembly procedures, careful planning and execution are vital for successful implementation. By understanding the nuances of this technique, engineers can optimize designs and ensure the reliability and longevity of their creations.

Question Bank

What are the common challenges in assembling interference fits?

Common challenges include part misalignment, material variations, and improper tooling. Careful handling and precision are essential to avoid these issues.

How do material properties impact interference fit design?

Material properties like elasticity and yield strength play a crucial role. Different materials require different tolerances and assembly methods to prevent damage or failure.

What are the different types of interference fits?

Types include tight, medium, and loose fits, each with varying tolerances and applications. The specific fit type depends on the required strength and functionality.

What are some troubleshooting steps for interference fit problems?

Troubleshooting often involves checking for misalignment, material defects, and improper assembly procedures. Detailed inspections and adjustments are usually necessary.