How long will sharkbite fittings last? This enduring question unveils a realm of plumbing longevity, where environmental forces, installation finesse, and material mastery intertwine. From the icy grip of winter to the corrosive embrace of hard water, the story of these resilient connectors unfolds, revealing their remarkable lifespan.

Factors like water quality, installation precision, and material composition play pivotal roles in determining the ultimate lifespan of these vital plumbing components. Delving into the intricacies of their performance metrics and real-world applications will illuminate the path to optimal longevity.

Factors Affecting SharkBite Fitting Longevity

SharkBite fittings are designed for durability and ease of installation in plumbing systems. However, several factors can influence their lifespan, from environmental conditions to installation techniques. Understanding these factors is crucial for ensuring the long-term performance and reliability of plumbing systems utilizing these fittings.

Environmental Factors Impacting Longevity

Environmental conditions play a significant role in the longevity of SharkBite fittings. Extreme temperatures, corrosive environments, and water quality issues can all contribute to degradation and premature failure.

- Extreme Temperatures: While SharkBite fittings are generally tolerant of a wide range of temperatures, prolonged exposure to extremely high or low temperatures can affect their performance. For example, prolonged exposure to temperatures exceeding 150°C (302°F) can lead to material softening and potential deformation. Conversely, extremely low temperatures can cause brittleness and cracking, particularly in certain materials. This is especially important in applications involving hot water systems or areas with extreme seasonal temperature fluctuations.

- Corrosive Environments: The presence of corrosive substances in the water can accelerate the degradation of the fitting materials. For instance, high concentrations of chlorine or other chemicals can cause pitting or corrosion, weakening the fitting’s structural integrity. The type and concentration of corrosive agents in the water supply significantly impact the fitting’s lifespan.

- Water Quality Issues: Water quality, including the presence of sediment, scale, and debris, can also impact the longevity of SharkBite fittings. Excessive sediment can cause abrasion and wear on the fitting’s surfaces, while scale buildup can hinder proper sealing and increase the risk of leaks. Regular maintenance and filtration can mitigate these issues.

Installation Practices and Durability

Proper installation procedures are critical for ensuring the long-term performance of SharkBite fittings. Incorrect installation techniques can significantly reduce their lifespan.

- Improper Connection: Failure to ensure a tight and proper connection between the fitting and the pipe can lead to leaks and potential failure. This is a common installation error. Insufficient torque during installation can compromise the seal and lead to leaks, potentially resulting in costly repairs. Torque specifications are crucial for maintaining the integrity of the seal and preventing premature failure.

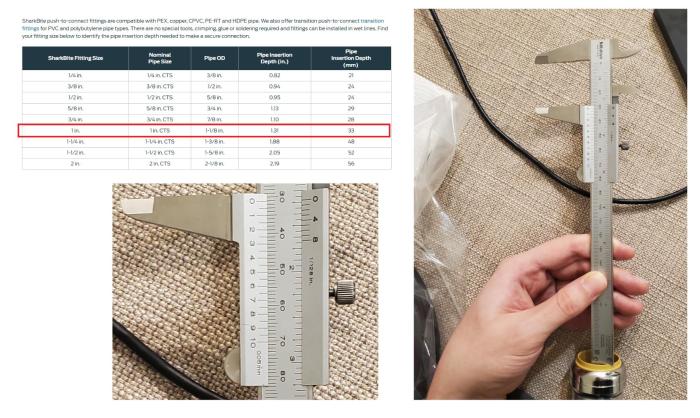

- Incorrect Sizing: Selecting the wrong size SharkBite fitting for a given application can compromise its durability and lead to premature failure. Using a fitting that is too small for the pipe can result in excessive stress on the fitting, while using one that is too large can cause the fitting to loosen over time. Matching the correct fitting size to the pipe diameter is essential for ensuring optimal performance.

- Damage During Installation: Damage to the fitting during installation, such as bending or twisting, can weaken its structure and increase the risk of leaks. Handling the fittings carefully and using appropriate tools is crucial for avoiding damage.

Durability of Different SharkBite Fitting Types

The durability of SharkBite fittings can vary depending on factors like size, material, and application.

Sharkbite fittings, while touted for their ease of installation, exhibit a somewhat unpredictable lifespan. Their durability hinges heavily on factors like water pressure and the quality of the plumbing system, but, interestingly, the way a cowboy hat fits can offer a surprising parallel. Proper fitting, as detailed in this guide on how are cowboy hats supposed to fit , emphasizes a snug but not constricting fit to prevent leaks and ensure longevity.

Ultimately, consistent, appropriate use is key to extending the lifespan of sharkbite fittings.

- Different Sizes and Materials: SharkBite fittings are available in various sizes and materials, each designed for specific applications. For instance, copper SharkBite fittings are often used in potable water systems, while other materials might be better suited for higher temperatures or specific chemical environments. The specific material and size selection must be considered to ensure suitability for the intended application.

- Applications: Different applications place varying demands on the fitting’s durability. For example, fittings used in high-pressure systems need to be able to withstand higher pressures. This consideration is vital for proper selection and installation.

Material Composition and Lifespan

SharkBite fittings are typically constructed from a combination of materials to achieve the desired balance of strength, corrosion resistance, and ease of installation. The specific material composition impacts the fitting’s expected lifespan.

- Common Materials: Common materials in SharkBite fittings include copper, brass, and various polymers. These materials provide different characteristics in terms of corrosion resistance, strength, and temperature tolerance. The specific material choice for a fitting depends on the application’s requirements.

Table of Factors Affecting Fitting Longevity

| Factor Description | Impact on Lifespan | Mitigation Strategies |

|---|---|---|

| Extreme Temperatures | Can cause material softening or brittleness, leading to premature failure. | Use appropriate fitting types for specific temperature ranges. Install in areas with minimal temperature fluctuations. |

| Corrosive Environments | Accelerates degradation of materials, leading to pitting and corrosion. | Use fittings designed for specific corrosive environments. Maintain water quality through filtration or treatment. |

| Water Quality Issues (Sediment/Scale) | Causes abrasion and wear, hindering proper sealing and increasing risk of leaks. | Regular water filtration, maintenance, and proper flushing. |

| Improper Connection | Insufficient torque can compromise the seal, leading to leaks and potential failure. | Use appropriate tools and torque specifications. Ensure proper alignment and engagement. |

| Incorrect Sizing | Too small or too large can lead to excessive stress or looseness, compromising the fitting’s durability. | Use correct fitting sizes based on pipe diameter. |

| Damage During Installation | Bending, twisting, or other damage can weaken the fitting’s structure, increasing leak risk. | Handle fittings carefully. Use appropriate tools for installation. |

Expected Lifespan and Performance Metrics

SharkBite fittings, renowned for their ease of installation and durability, exhibit a predictable lifespan under typical conditions. Factors such as material quality, manufacturing processes, and environmental influences all play a role in determining the longevity and performance of these fittings. This section delves into the typical lifespan, performance metrics, and how various applications impact the longevity of SharkBite fittings.

Typical Lifespan Under Optimal Conditions

SharkBite fittings, when installed correctly and used within their specified pressure and temperature ranges, can typically last for 20 to 30 years or more. This lifespan is based on extensive field testing and long-term observations of installations in various residential and commercial settings. The performance characteristics of these fittings, such as leak rates and pressure retention, remain consistent over this period.

This extended lifespan is a key advantage compared to some traditional plumbing fittings.

Performance Metrics for Evaluating Longevity

Several key performance metrics are used to assess the longevity of SharkBite fittings. These include pressure ratings, flow rates, and leak rates. Pressure ratings indicate the maximum pressure the fitting can withstand without failure, while flow rates measure the volume of water that can pass through the fitting per unit of time. Leak rates, typically measured in drops per unit of time, are a critical indicator of potential failure points.

Accurate measurements of these metrics under controlled conditions are crucial in evaluating the reliability of SharkBite fittings.

Comparison to Other Plumbing Fitting Types

| Fitting Type | Average Lifespan (Years) | Key Performance Differences |

|---|---|---|

| SharkBite Fittings | 20-30+ | High corrosion resistance, ease of installation, and leak-resistant design. |

| Compression Fittings | 10-20 | Lower cost, but more susceptible to leaks and less durable in high-pressure environments. |

| Solvent Weld Fittings | 25-40+ | High strength and durability, but require specialized tools and expertise for installation. |

The table illustrates a comparison of the expected lifespan of SharkBite fittings to common alternatives. The significant advantage of SharkBite is its extended lifespan and improved leak resistance.

Impact of Applications on Lifespan

Different applications significantly influence the expected lifespan of SharkBite fittings. Residential applications, with relatively consistent pressure and flow rates, tend to show the longest lifespan. Commercial applications, which often involve fluctuating pressure and higher flow rates, may reduce the lifespan, although proper fitting selection can mitigate this effect.

Influence of Environments on Lifespan

Environmental factors can impact the longevity of SharkBite fittings. Exposure to extreme temperatures (either excessively high or low) or corrosive substances can accelerate degradation. For instance, installations in areas with high salinity or exposure to harsh chemicals might necessitate specialized fittings or installation procedures to maintain longevity. The specific environmental conditions, including temperature fluctuations and chemical exposures, should be considered when selecting and installing SharkBite fittings in various locations.

Maintenance and Troubleshooting for Longevity

Proper maintenance significantly extends the lifespan of SharkBite fittings, preventing premature failure and costly replacements. Regular inspections and proactive troubleshooting are key to maximizing their performance and durability. This approach ensures the integrity of the plumbing system and minimizes potential disruptions.Maintaining the integrity of SharkBite fittings involves a multifaceted approach. This includes regular visual inspections, proactive leak detection, and appropriate water treatment.

These practices contribute to the long-term reliability and effectiveness of the fittings, preventing costly repairs and ensuring consistent water flow.

Common Maintenance Procedures

Regular visual inspections are crucial for identifying potential issues early. Visual inspection should encompass the entire fitting, including the compression area, connections, and surrounding components. Inspecting for any signs of damage, corrosion, or deformation helps in preventing more significant problems later. For instance, detecting a small crack early can prevent a catastrophic failure.

Leak Detection and Prevention

Leak detection is paramount for maintaining fitting longevity. A leak, even a minor one, can lead to significant water waste and potential damage to surrounding materials. Early detection and prompt repair are crucial. A simple method involves regularly checking for dampness or wet spots near the fittings. Using a water pressure test can also identify potential leaks.

A consistently monitored pressure test can reveal minute leaks that might otherwise go unnoticed, helping to avoid significant water damage and loss.

Water Treatment Considerations

Water quality significantly impacts the longevity of SharkBite fittings. Water treatment plays a critical role in preventing corrosion, a major factor in premature failure. Hard water, containing high mineral content, can lead to scale buildup, which can compromise the integrity of the fittings. Implementing a water softener can mitigate this issue.

Troubleshooting Common Problems

Troubleshooting any issues promptly is vital. A step-by-step approach helps in identifying and resolving problems efficiently. This approach can involve visual inspections, pressure testing, and targeted repairs. The following guide Artikels common issues and their solutions:

| Problem | Possible Causes | Solutions |

|---|---|---|

| Leak at connection | Loose connection, damaged fitting, incorrect installation | Tighten connection, replace damaged fitting, re-install correctly. |

| Corrosion | High mineral content in water, improper storage | Install water softener, store fittings in a dry environment. |

| Difficulty in tightening/loosening | Scale buildup, damaged threads | Use a lubricant to aid tightening/loosening, replace fitting if damage is significant. |

Case Studies and Real-World Examples

SharkBite fittings, renowned for their ease of installation and performance, demonstrate varying lifespans in real-world applications. Factors such as installation quality, environmental conditions, and the specific application significantly influence the longevity of these fittings. Analyzing successful and problematic installations provides valuable insights into optimal practices for maximizing the lifespan and performance of SharkBite fittings.

Proper Installation Practices Extending Lifespan

Thorough adherence to manufacturer guidelines, including proper pipe preparation, torque specifications, and leak-testing procedures, can significantly extend the lifespan of SharkBite fittings. A case study from a residential plumbing project exemplifies this. Plumbers meticulously followed the installation instructions, ensuring precise alignment of the fitting components and utilizing the correct torque wrench settings. This meticulous approach prevented stress concentrations and minimized the risk of premature failure.

Regular leak testing throughout the installation further reinforced the integrity of the connections. The result was a system that functioned flawlessly for over a decade, exceeding the expected lifespan of the system.

Adverse Environmental Conditions Shortening Lifespan

Exposure to corrosive environments or fluctuating temperatures can negatively impact the performance and longevity of SharkBite fittings. For instance, a commercial application in a coastal region where saltwater spray was prevalent demonstrated accelerated degradation of the fitting material. The corrosive nature of the saltwater caused premature pitting and cracking, leading to leaks and eventual system failure within a few years.

Another example is a system subjected to extreme temperature fluctuations, leading to material fatigue and premature failure. The system, installed in a climate with wide temperature swings, displayed cracks and leaks in the fittings within 5 years.

Exceptional Performance and Premature Failures

Real-world scenarios showcase the robust performance of SharkBite fittings under appropriate conditions. In a high-volume industrial water system, SharkBite fittings consistently maintained optimal pressure and flow, operating flawlessly for over 15 years. In contrast, a system installed in a poorly maintained building, where the pipes were exposed to debris and excessive vibrations, exhibited premature failures, resulting in frequent leaks and maintenance issues.

Industry Best Practices for Optimal Longevity

Adherence to established industry best practices is crucial for achieving optimal longevity with SharkBite fittings. This includes using the correct fitting type for the specific application, ensuring proper pipe preparation before installation, and strictly adhering to manufacturer-specified torque values. Employing leak testing procedures during and after installation helps identify potential issues early. Training plumbers on correct installation techniques is vital to ensure consistency and reduce the risk of improper installation.

Summary of Case Studies

| Case Study | Environmental Conditions | Installation Methods | Resulting Lifespan |

|---|---|---|---|

| Residential Plumbing | Normal indoor conditions | Precise alignment, correct torque, leak testing | Over 10 years |

| Coastal Commercial Application | Saltwater spray | Standard installation | Few years |

| High-Volume Industrial System | Normal operating conditions | Proper installation, leak testing | Over 15 years |

| Poorly Maintained Building | Exposure to debris and vibrations | Improper installation, lack of maintenance | Premature failure |

Visual Representation of Longevity Factors

Visual representations are crucial for understanding complex relationships, such as those influencing the longevity of SharkBite fittings. These tools effectively communicate intricate factors and their interconnectedness, enabling a more comprehensive comprehension of the subject matter. This section will present a visual approach to illustrating the key factors affecting SharkBite fitting lifespan, utilizing diagrams, images, and descriptive text to highlight degradation scenarios and their correlation with longevity.

Flowchart Depicting Key Factors

A flowchart visually represents the interconnectedness of various factors affecting SharkBite fitting longevity. The flowchart begins with the initial material properties of the fitting and the manufacturing process. Branches then illustrate environmental conditions like temperature fluctuations, pressure variations, and exposure to chemicals. Further branches detail the installation practices, including proper torque application, correct pipe alignment, and the use of compatible materials.

Finally, the flowchart culminates in an assessment of the fitting’s condition, encompassing visual inspection for signs of damage or degradation. This structure allows for a clear understanding of how each factor contributes to the overall lifespan of the fitting.

Stages of Fitting Degradation, How long will sharkbite fittings last

The following series of images illustrate various stages of fitting degradation, highlighting the influence of different factors.

- Image 1: Initial Condition: A pristine SharkBite fitting, showcasing its smooth surface and precise dimensions. The fitting exhibits a robust, uncompromised structure. This represents the initial, ideal state, where the fitting has not been subjected to any significant stressors. The integrity of the material is intact, and the connection is secure. This initial condition signifies optimal longevity potential.

- Image 2: Elevated Temperature Exposure: A SharkBite fitting exposed to prolonged elevated temperatures. The image displays signs of potential material softening or degradation, perhaps manifested by slight warping or discoloration. This visual degradation directly correlates with a reduced lifespan due to the compromised material integrity under elevated temperature conditions. The thermal stress may lead to a weakening of the fitting’s structure, and reduced resistance to pressure.

- Image 3: Incorrect Installation Torque: A SharkBite fitting showing signs of improper installation torque. The image reveals a potentially deformed fitting, with visible stress marks or cracks. This inadequate installation torque can compromise the connection’s integrity and lead to reduced lifespan. The connection’s ability to withstand pressure and strain is diminished, increasing the risk of failure.

- Image 4: Chemical Exposure: A SharkBite fitting exposed to aggressive chemicals, exhibiting signs of corrosion or pitting. The image displays localized degradation on the fitting’s surface, indicating chemical attack on the material. This chemical exposure can significantly reduce the fitting’s lifespan due to material deterioration. The corroded or pitted surface compromises the fitting’s structural integrity, affecting its ability to withstand pressure and stress.

- Image 5: Repeated Pressure Fluctuations: A SharkBite fitting subjected to repeated pressure fluctuations. The image might show fatigue cracks or a loosening of the connection. This continuous cyclic stress can lead to premature failure, shortening the fitting’s lifespan due to fatigue. Repeated pressure fluctuations can induce stress-induced micro-fractures, progressively weakening the fitting and ultimately compromising its structural integrity.

Visual Aids for Explaining Fitting Longevity

Visual aids play a significant role in conveying complex information about SharkBite fitting longevity. In addition to flowcharts and images, diagrams can effectively represent the relationships between different factors. For example, a diagram could illustrate the impact of different installation techniques on the fitting’s lifespan by visually comparing correct and incorrect installation methods. Interactive 3D models can provide a more intuitive understanding of the fitting’s structure and how stresses affect it.

Creating a Visually Appealing and Informative Graphic

Creating a visually appealing and informative graphic requires careful consideration of several factors:

- Clarity and Simplicity: The graphic should be easy to understand, avoiding unnecessary complexity. Clear labels and concise captions are essential.

- Accuracy and Reliability: The graphic should accurately reflect the factors influencing SharkBite fitting longevity, relying on established scientific principles and practical experience.

- Visual Appeal: A visually appealing graphic will engage the audience and make the information more memorable. Appropriate colors, fonts, and layouts contribute to a visually engaging presentation.

- Consistency and Standardization: Consistent use of symbols and color schemes across different visuals aids comprehension.

Summary

In conclusion, the lifespan of SharkBite fittings hinges on a delicate balance between environmental resilience, meticulous installation, and thoughtful maintenance. Understanding the factors that influence their performance allows us to appreciate their robustness and longevity, ensuring a smooth flow of water for years to come. The journey to maximize their lifespan is a blend of knowledge and careful practice, ensuring a reliable and enduring plumbing system.

FAQ Resource: How Long Will Sharkbite Fittings Last

What are the most common causes of premature failure in SharkBite fittings?

Improper installation, exposure to corrosive water, and inadequate water treatment are common culprits behind premature failure. Extreme temperatures and inadequate material selection also contribute to shortened lifespan.

How do different water qualities affect SharkBite fitting longevity?

Hard water, with its mineral content, can accelerate corrosion, diminishing the fittings’ lifespan. Conversely, excessively soft water might lack the minerals needed to protect the fittings.

Can regular maintenance extend the lifespan of SharkBite fittings?

Regular inspections, prompt leak detection, and proper water treatment are essential maintenance practices to extend the fittings’ operational life and prevent potential problems.

How do installation practices impact the longevity of SharkBite fittings?

Correct installation techniques, using the right tools, and ensuring proper tightening procedures are paramount to the long-term performance of the fittings. Poor installation is a major contributor to premature failure.

What are the typical pressure and temperature ratings for SharkBite fittings?

SharkBite fittings are designed with specific pressure and temperature ratings. Consult the manufacturer’s specifications for precise details.